PCBA Solutions

With state-of-the-art SMT, AOI, and advanced storage systems, backed by a highly experienced team, we're equipped to tackle even the most complex electro-mechanical assembly challenges. Explore our capabilities below to see how we can support your next project.

OVERVIEW

With ZOT, a single purchase order takes care of all your electronic assembly needs. We provide a complete electronics manufacturing service that includes Surface Mount Technology, selective soldering, through-hole assembly, and full-scale final box assembly.

Our highly skilled and experienced team of engineers and technicians, backed by continuous investments in SMT lines, selective soldering and automated storage solutions, provide you with exceptional precision, consistency, and speed in every build.

Our commitment to excellence means, we invest in our equipment and people by training our team to IPC standard. All your products will go through our Automated Optical Inspection to secure a reliable service every time you order with us.

OUR EXPERTISE

Precision assembly backed by decades of experience

Industry-Leading Expertise

Our PCBA team is trained to the highest industry standards, with continuous development supported by internal IPC-certified training programs. Their versatility and talent are evident in every product we deliver, from complex assemblies to full box builds. Their expertise ensures rapid turnaround times and gives our customers the confidence that every project is in capable hands.

From prototypes to production runs, our team's comprehensive knowledge allows us to deliver exceptional quality on every project, with the added advantage of seamless integration with our PCB and sheet metal divisions.

IPC Certified Assembly

Our technicians are trained to IPC-A-610 for PCB assembly and IPC-A-620 for electro-mechanical assembly standards.

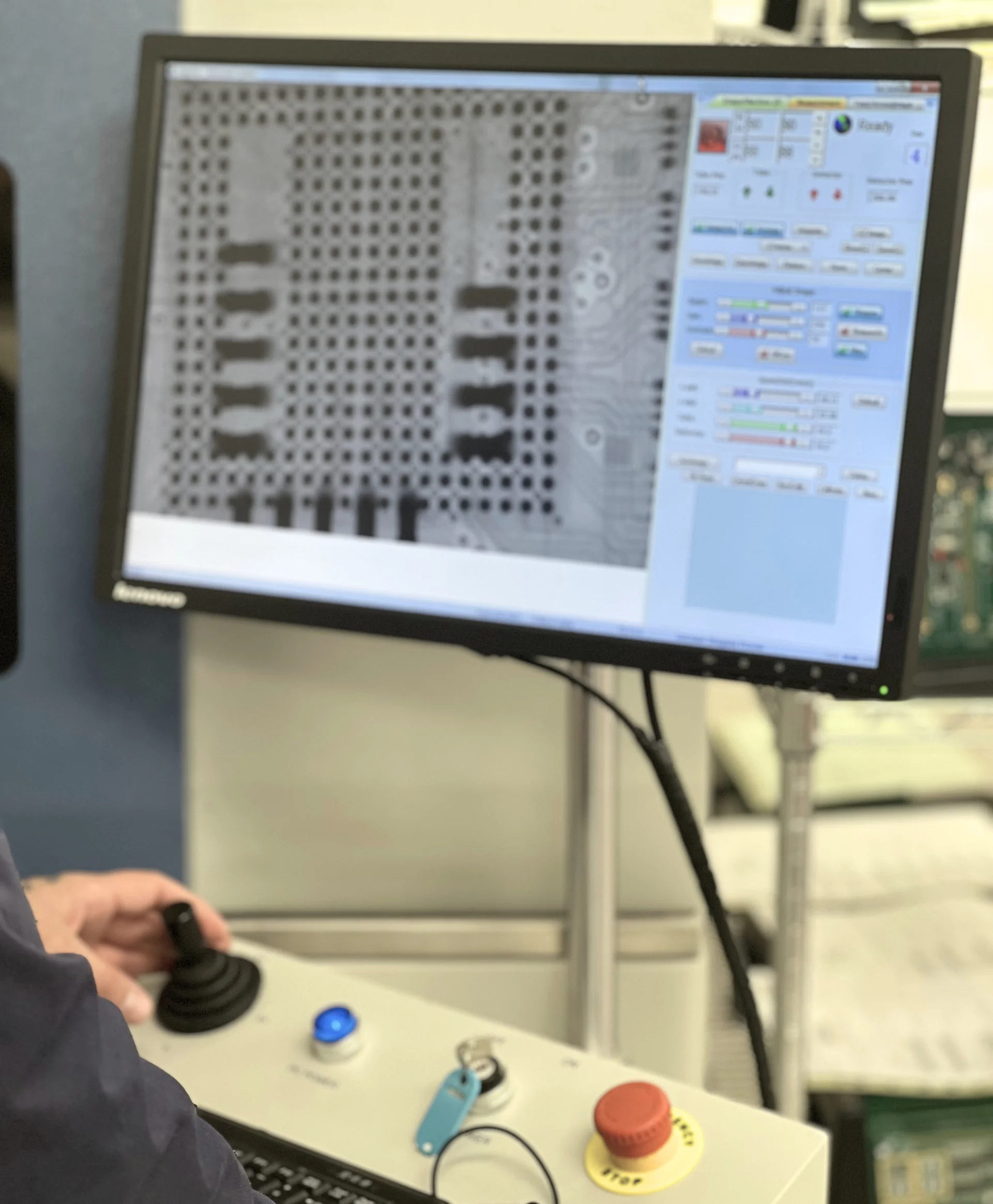

Advanced Inspection Systems

Automated Optical Inspection (AOI) and X-ray inspection ensure comprehensive defect detection for reliable assemblies.

Full Box Build Capabilities

Complete system integration from PCB assembly to fully assembled and tested electro-mechanical products.

Advanced Assembly Technologies

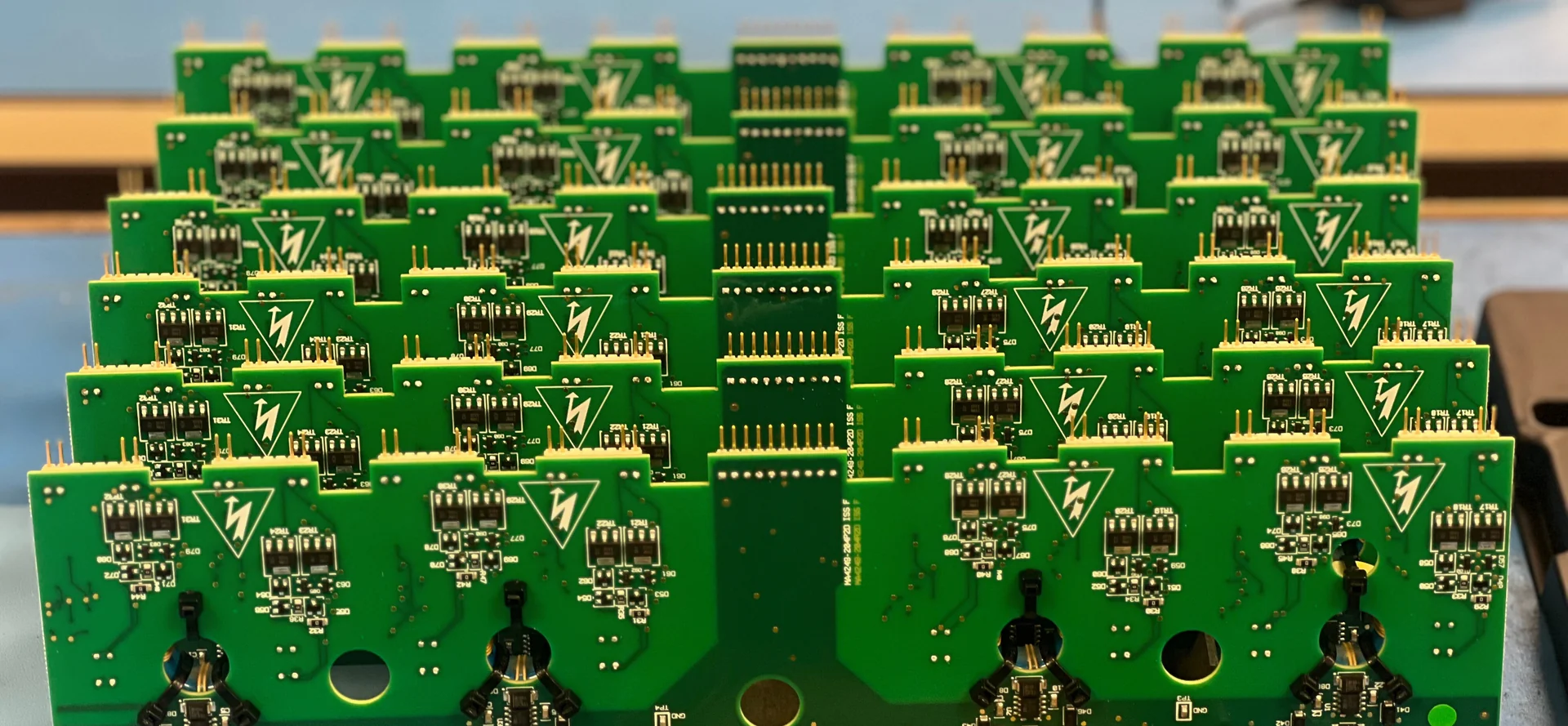

Our state-of-the-art PCBA facility features cutting-edge equipment for surface mount and through-hole assembly, enabling us to handle a wide range of component types and board complexities with precision and efficiency.

Surface Mount Technology

Our state-of-the-art SMT production line offers high-speed, high-precision component placement for a wide range of surface mount components, from the smallest 01005 packages to large QFPs and BGAs.

- Surface Mount Placement up to 24000cph

- SMT Placement from 01005 up to 140mm x 73mm

- BGA and fine-pitch component placement

Through-Hole Assembly

In addition to advanced SMT capabilities, we provide comprehensive through-hole assembly services. From manual soldering to automated selective soldering, we ensure reliable connections for all through-hole components.

- Selective soldering technology

- Wave soldering capability

- Hand soldering by IPC-certified technicians

Box Build Assembly

Our box build assembly services provide complete system integration, from PCBAs to fully assembled and tested products. We handle all aspects of the assembly process, including mechanical assembly, cabling, and final product testing.

- Full electro-mechanical assembly

- Cable and harness fabrication

- System integration and testing

OUR ASSEMBLY PROCESS

A systematic approach to delivering quality electronic assemblies

Project Planning

Initial consultation to understand requirements and develop a tailored assembly plan.

Component Procurement

Sourcing and managing all required components with full traceability.

SMT Assembly

Automated placement and soldering of surface mount components.

Through-Hole Assembly

Manual or automated assembly of through-hole components.

Inspection & Testing

Comprehensive inspection and testing to ensure quality and functionality.

Box Build & Integration

Complete system assembly including mechanical parts and cabling.

Final Testing

Functional testing of completed assemblies to validate performance.

Packaging & Delivery

Custom packaging and shipping to your location or direct to customers.

Ready to start your PCBA project?

Contact our team today to discuss your assembly requirements and discover how we can deliver the perfect solution for your electronics manufacturing needs.