Printed Circuit Boards

With continuous investments in equipment & training of our versatile, highly skilled team, we're ready to meet all your PCB manufacturing and fabrication needs. Learn more about what we can do for you below.

OVERVIEW

From rigid and multi-layer boards to flex-rigid and HDI technology, our PCB division offers you a complete range of advanced and truly bespoke electronic manufacturing solutions tailored to your specific requirements.

Whether you need low or medium volume production and fast turnaround, we've got your back! For high-volume needs, our offshore division ensures scalable, cost-effective solutions.

With all our facilities based in one location, we can offer you a quick turnaround and process control unmatched on the market.

OUR EXPERTISE

Five decades of innovation and technical excellence

Industry-Leading Expertise

Our specialist PCB team understands your electronics manufacturing needs inside and out. By fostering a strong culture of internal development and promotion, we retain top-tier manufacturing expertise and ensure continuity across every project. This stability translates directly to our customers, providing confidence that we'll be there to meet their needs, time and time again.

With over five decades of combined experience, our engineers and technicians have worked on projects across every major industry sector, developing specialized knowledge that allows us to tackle complex challenges with confidence.

ISO Certified Manufacturing

Our facilities maintain ISO 9001:2015, ISO 14001, and AS9100D certifications, ensuring the highest quality standards across all PCB projects.

Standard and advanced technology

Well established and documented processes, as well as investments in engineering time in order to provide a significant technical PCB advantage.

Continuous Training

Our team undergoes regular training and certification to stay at the forefront of electronics manufacturing technology and techniques.

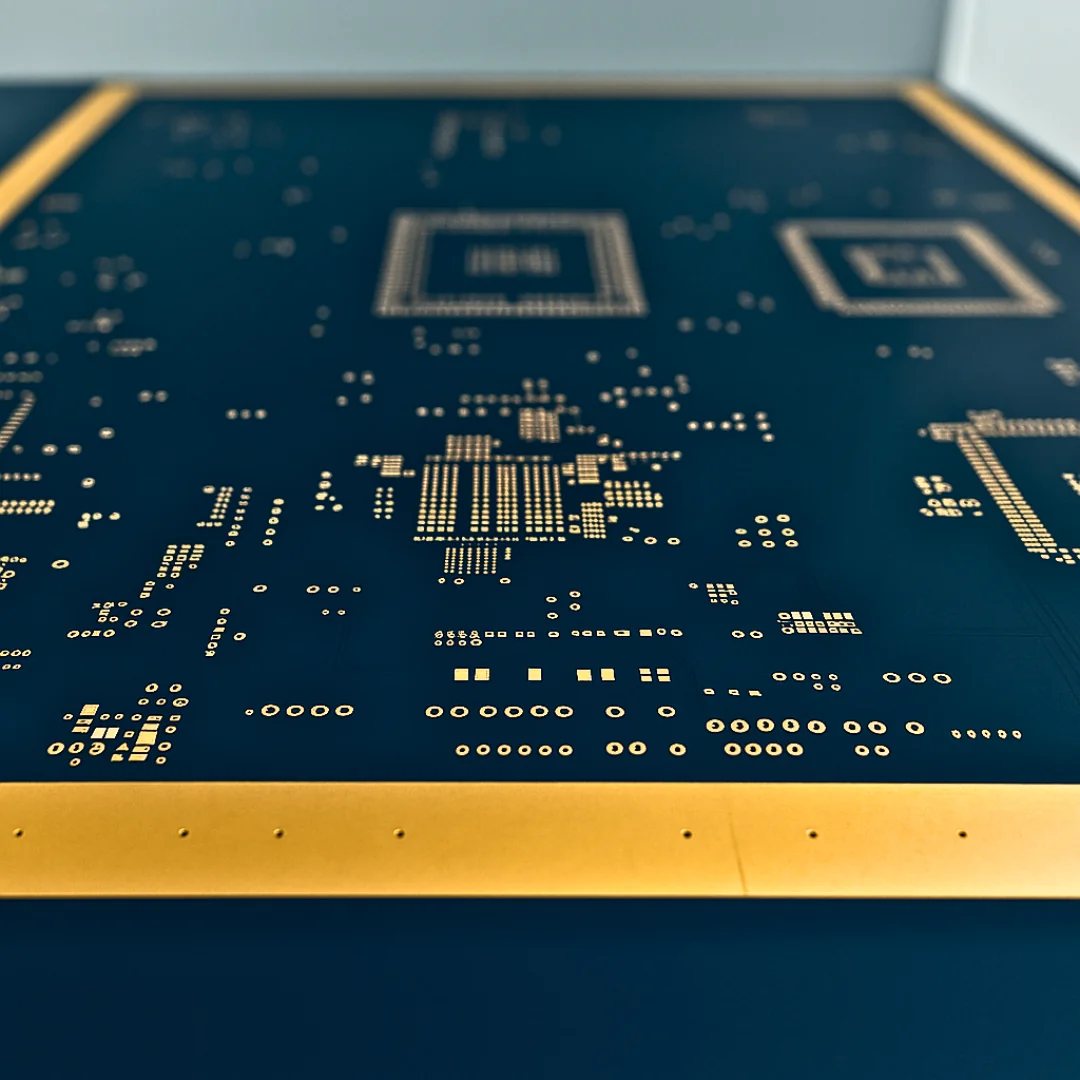

Advanced Manufacturing Capabilities

Our state-of-the-art facilities feature the latest in PCB manufacturing technology, enabling us to tackle complex projects with precision and efficiency. With significant investments in equipment and processes, we maintain cutting-edge capabilities that set industry standards.

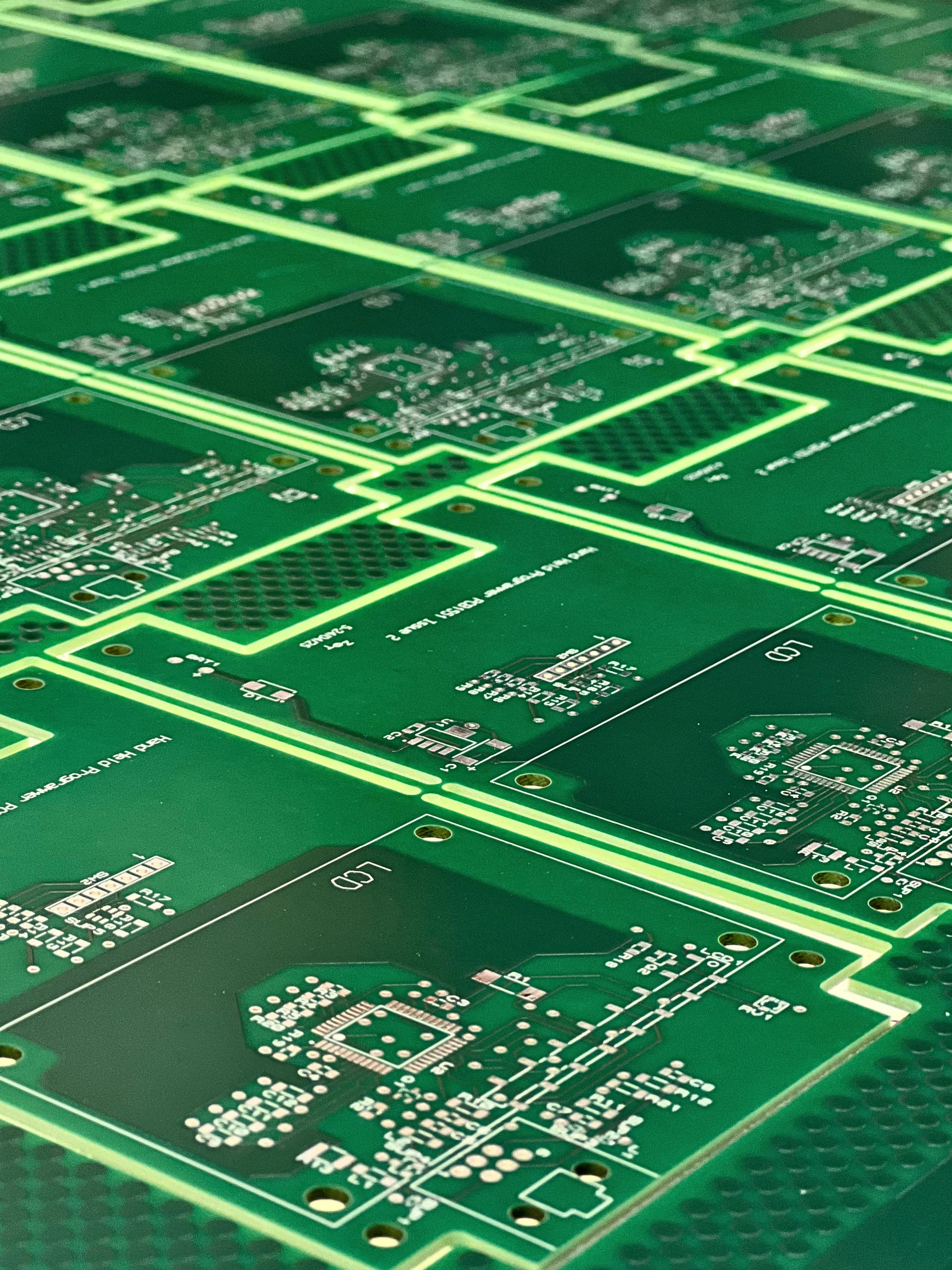

Rigid / Multi Layer

ZOT offers a full range of rigid board constructions from single/double sided up to 24 layers and beyond, with vast experience in high layer count / high technology boards. We have continually invested not only in the equipment and processes to allow the production of these high technology boards, but also in the latest test and inspection equipment to ensure the highest quality.

- High layer count multilayer

- FR4 / Polyimide / High Speed / Special Materials

- Controlled Impedance

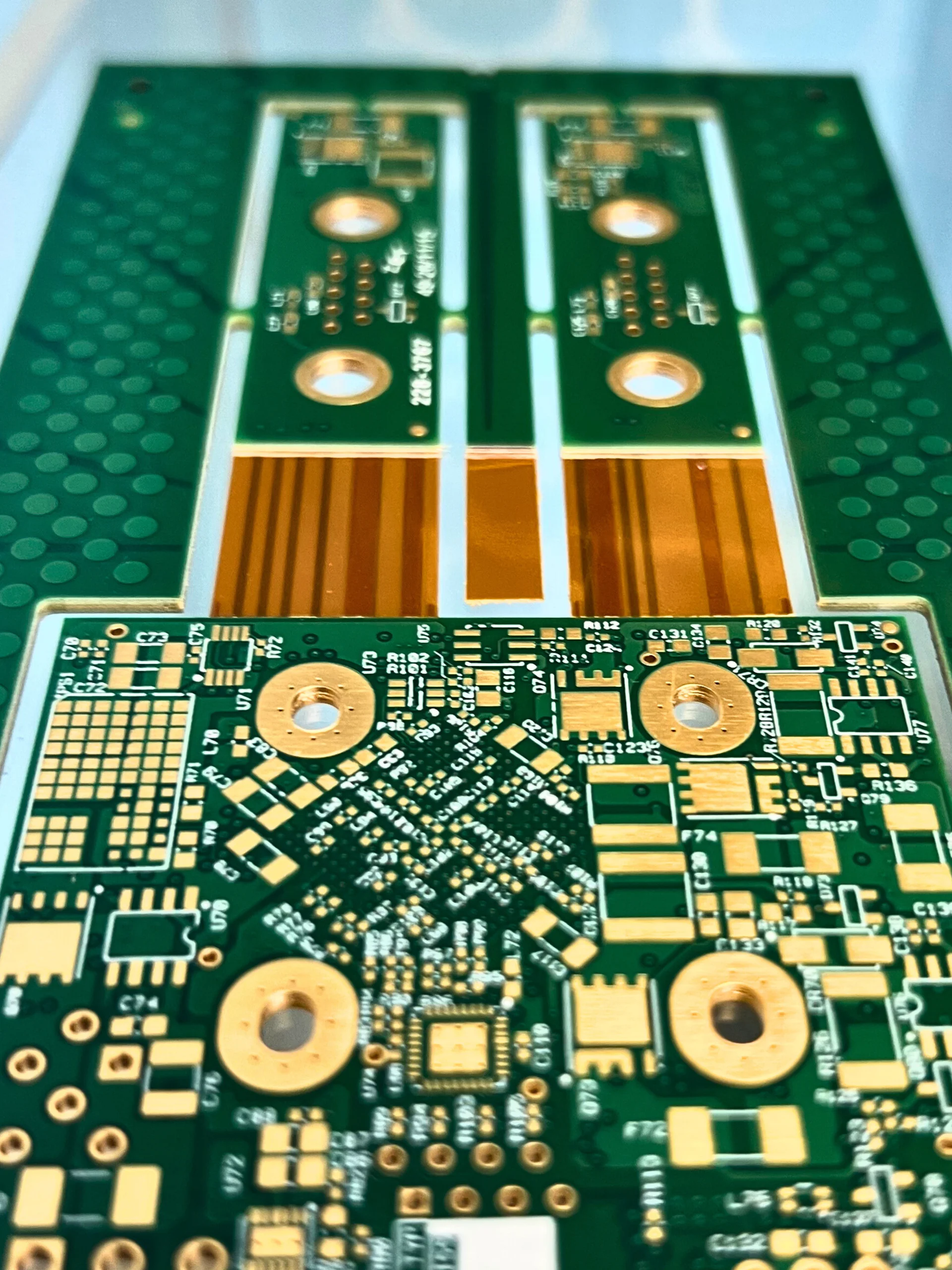

Flex-Rigid

ZOT's full range of flex / flexi rigid products features double sided flex, multilayer flex, and multilayer flexi rigid designs. Depending on design requirements, these can incorporate advanced technologies like micro via, sequential build up, internal/external heatsinks, and solutions for high-speed applications.

- Double sided flex

- Multilayer flex

- High speed applications

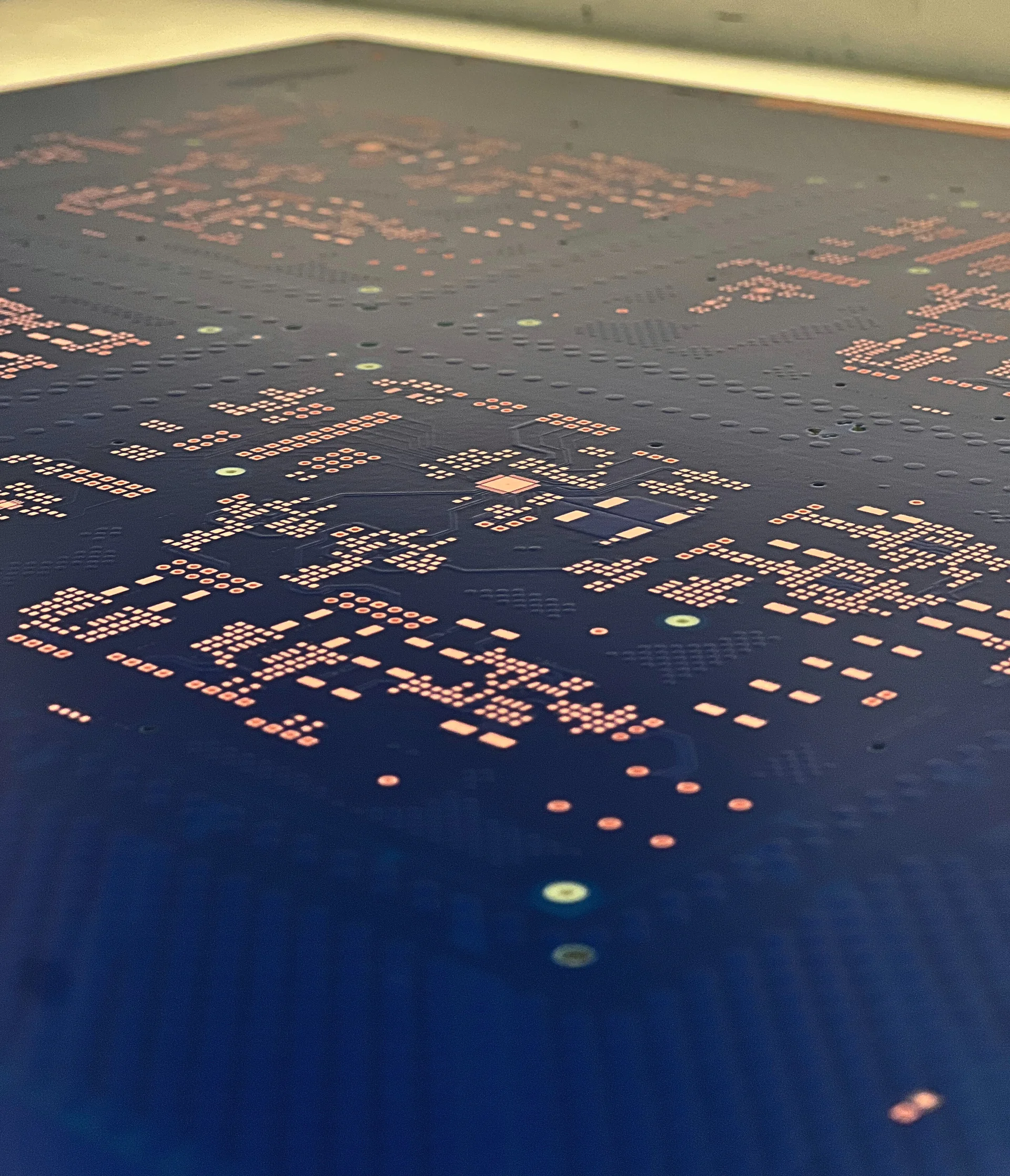

HDI - Sequential Build Up

With the increasing component densities demanded by today's technology, sequential build-ups are often the only viable solution for the PCB construction. ZOT has extensive experience producing these types of construction, incorporating buried, blind and micro vias in a range of combinations to meet the most demanding design requirements.

- Standard micro via

- Copper filled micro via

- Stacked micro via (3 layers +)

OUR MANUFACTURING PROCESS

Advanced technology and strict quality controls at every stage

Design Review

Our PCB engineers review your design files for manufacturability and suggest optimizations if needed.

Production Setup

We prepare production panels, PCB tooling and manufacturing parameters based on your specifications.

Fabrication

Using state-of-the-art production equipment, we fabricate your PCBs with precision and attention to detail.

Quality Control

Rigorous testing and inspection procedures ensure every printed circuit board meets our high quality standards.

Delivery

Carefully packaged and shipped to your location, with full documentation and traceability.

Ready to start your PCB project?

Contact our team today to discuss your PCB requirements and discover how we can deliver the perfect solution for your needs.